madhatter66

Active member

- Joined

- Sep 12, 2013

- Messages

- 85

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 34' CONVERTIBLE (1965 - 1969)

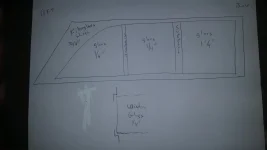

I'm looking into replacing the side windows on my 34C. The tinted plexiglass with be secured using the 3M 5962 VHB with a caulking of Dow 795. The plexi will be either 3/8 or 1/2in. Will replacing the glass windows with plexi cause a structural issue for the flybridge? The front windshields have already been removed and replaced with plywood and 2 layers of fiberglass. I was hoping to use a 1 piece but due to limited mainly lack of availability I think I have to go with 2 pieces and joint togehter. Plan for using 2 pieces will have me placing an added support in the middle of the window opening. Plywood attached to the topside and fiberglass over. The window opening is an estimated 32" height 9.5ft length. This will est break down each piece to 35" height 5ft length. Thx