HahnR

Active member

- Joined

- Jul 27, 2015

- Messages

- 137

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 58' MOTOR YACHT-Series I (1977 - 1980)

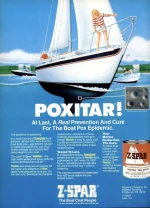

OK, last fall when we got pulled, we had the blisters blasted off & the boat has been in inside heated storage all winter, so everything is good & dried out. Now is the time for a barrier coat. Our marina is recommending coal tar epoxy rather than a 2 part epoxy barrier coat and bottom paint. They claim it is a much more durable product and will seal the blisters better than a barrier coat. I had never heard of it before, has anyone ever used it & would you recommend it? Looks like it is more commonly used on steel

Randy

Randy