Vincentc

Legendary Member

- Joined

- Jun 3, 2008

- Messages

- 1,514

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 43' DOUBLE CABIN (1970 - 1984)

I reworked and rebedded the port side cabin windows with boatlife polysulfide sealant shortly after we got the boat and within no time I had small leaks between the aluminum frame and the cabin side.

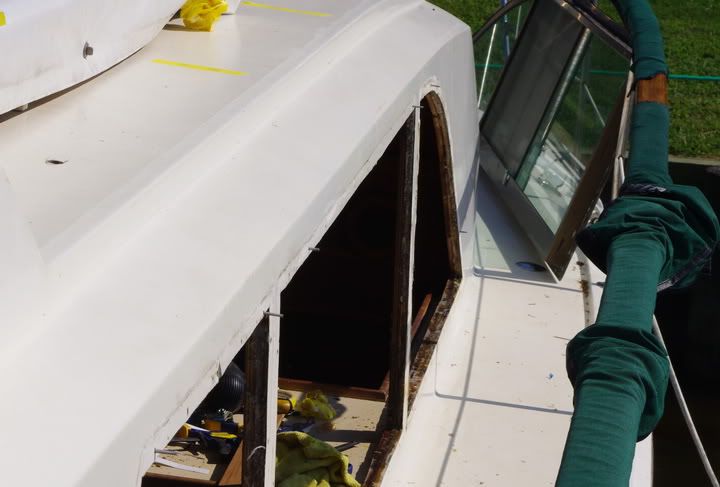

Once the rain stopped after TS Lee I removed the windows, old caulk and set out to remove and epoxy the rotten coring on the stb side windows, which I did not get to last time. A PO had apparently bedded the stb window frames with silicone caulk/sealant but did nothing for the coring.

I struggled with the quandray of sealant choices and searched the forum and other internet sites. My review of process recommended by Sams for glazing the fixed windows got me thinking about adapting its use of buty tape to my project. I also found this site and comments on Butyl tape interesting:

http://www.pbase.com/mainecruising/rebedding_hardware

I decided to use butyl tape to bed the aluminum window frames coupled with sealant out of the caulking gun. The tape does not easily compress and should allow a thick and consistent bead of sealant around the outer edge of the frame.

I am also going to bed the stainless screw heads with butyl to seal them and insulate the aluminum from the stainless.

I purchased some 1/8 x 3/8" butyl tape from a glass company and am running the tape around the perimeter of the window frame leaving a 1/4" gap from the outside edge. After applying the buty tape to the aluminum frame I ran a thick bead of 3M 4200 around the outside perimeter of the port window frame. I plan on using RTV Silicone on the stb side since silicone was previously applied there. I was impressed with how well the silicone still stuck to the aluminum and fg.

I installed one port frame last night and hope to get the rest rebedded tonight.

I'll let you know how it works and may remember to take some pictures tonight.

While I am working on the windows, my son is painting the bottom of the Oday without a haulout. I did get a picture of that.

Regards,

Vincent

Once the rain stopped after TS Lee I removed the windows, old caulk and set out to remove and epoxy the rotten coring on the stb side windows, which I did not get to last time. A PO had apparently bedded the stb window frames with silicone caulk/sealant but did nothing for the coring.

I struggled with the quandray of sealant choices and searched the forum and other internet sites. My review of process recommended by Sams for glazing the fixed windows got me thinking about adapting its use of buty tape to my project. I also found this site and comments on Butyl tape interesting:

http://www.pbase.com/mainecruising/rebedding_hardware

I decided to use butyl tape to bed the aluminum window frames coupled with sealant out of the caulking gun. The tape does not easily compress and should allow a thick and consistent bead of sealant around the outer edge of the frame.

I am also going to bed the stainless screw heads with butyl to seal them and insulate the aluminum from the stainless.

I purchased some 1/8 x 3/8" butyl tape from a glass company and am running the tape around the perimeter of the window frame leaving a 1/4" gap from the outside edge. After applying the buty tape to the aluminum frame I ran a thick bead of 3M 4200 around the outside perimeter of the port window frame. I plan on using RTV Silicone on the stb side since silicone was previously applied there. I was impressed with how well the silicone still stuck to the aluminum and fg.

I installed one port frame last night and hope to get the rest rebedded tonight.

I'll let you know how it works and may remember to take some pictures tonight.

While I am working on the windows, my son is painting the bottom of the Oday without a haulout. I did get a picture of that.

Regards,

Vincent